- I guess, the

first question anyone would ask me is "Why?". Why build it

yourself when you can get them so inexpensively? Let's face

it, Summit Racing offers it for less than $30 complete! Cool

factor and sense of accomplishment are the first things I

respond, plus it gives you a range of mounting options you

don't have in a pre-canned package, like how about a stealth

mount in the dash or gauges. In addition, these have an

adjustment feature that lets you "tune" the gauge for more

detail that the big makers don't give you and an adjustable

brightness control. In any case, these can be done for around

$10-$15 easily and are every bit as accurate as many others

that you pay bigger bucks for.

-

- Parts

List

-

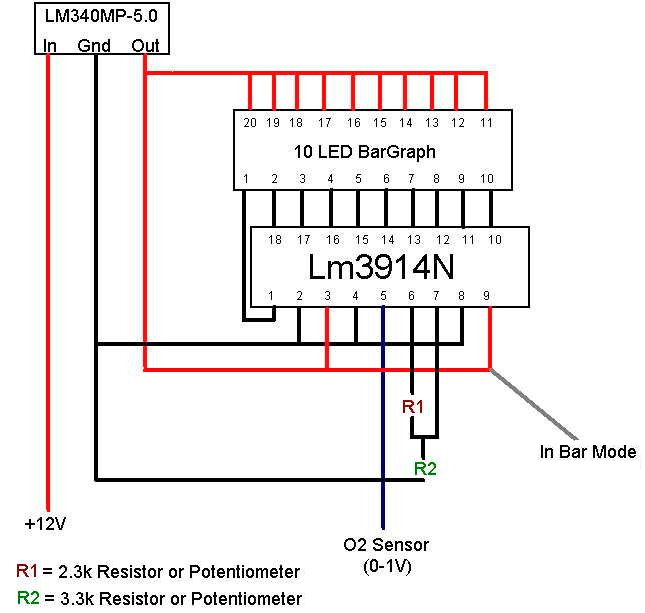

- DOT/Bar

Display Driver - National Semiconductor

LM3914N

Voltage Regulator -

National Semiconductor

LM340MP-5.0

or Radio Shack

#276-1770

- 10

Segment LED BarGraph - Radio Shack

#276-081

-

Resistors (2.3k

and

3.3k)

- Mini

Circuit Board - Radio Shack

#276-148

Misc Wires as needed

- 18 Pin

socket - Radio Shack

#900-5741

- 20 Pin

socket - Radio Shack

#900-5742

-

Optional Parts:

The Run

Down

My first

suggestion is to always use chip sockets when soldering to

chips. This way the chip itself doesn't take any heat causing

potential failure and undue headaches in trying to troubleshoot.

If you solder a bunch of wires from the chip socket to the LED

socket you can have some placement flexibility for the LED

display, like in the dashboard. Be aware that LED's have a

Positive side and Negative side. There's a flat spot in the

corner of the BarGraph 'chip' to indicate Pin 1.

There are

many different ways to make this a clean, well executed project,

but as always, the end result is from your own efforts. Such

niceties as terminating the wires with connectors and what not.

You can also use floppy drive ribbon cables to connect all the

circuits together, which will make it easy and neat to mount the

LED graph separately.

Most

people want the wide band of the O2 measuring from 0-1v. But

some might want a Finer Resolution. Where it'll measure from

0.4-1v. This would mean that the 1st LED will be ~0.4v and the

10th LED will be 1v. Engines equipped with a turbo, blowers, or

Nitrous, might want a finer resolution as the Air / Fuel ratio

is especially critical for those motors. In a Naturally

Aspirated engine, the finer resolution might not be necessary as

the proper mixture (14.7:1) is at about 0.5v from the O2 sensor.

Resistor

R1 is what determines the resolution for the LED display.

Resistor R2 is what determines the relative brightness of the

LED. You can stick potentiometers in place of these resistors in

order to fine tune the bar graph resolution and display

brightness and is highly encouraged for flexibility. If you

decide to use the Potentiometer (POT) you need to get an Ohm

meter and measure the range at which resistance ranges from 2.3k

to 3.3k . As it is adjustable, you can adjust it on the fly.

In order

to run the display at the finest resolution possible, take out

R1 and run it straight with no resistor in there. It should be

that simple. During experimentation I had the resolution up to

0.7v as the 1st led, but I can't figure what was done to get

this measurement. Feel free to play around with it and let us

know if you find something that works better.

Currently

it is setup as BAR mode. If you prefer DOT mode, disconnect pins

3 and 9. DOT mode is when one LED will light up at a time, while

BAR mode all lights will light up, building to the final value.

Installation is as straight forward as it could be. Hook

up the power to an to a switched power source, and connect up

the ground to a solid ground. Connect up the Signal Wire to your

O2 sensor. Remember that your ECU will need signal too for fuel

adjustment. Note: the voltages from the O2 sensor are

very low, so take extra care in taping the signal wire and make

a high quality connection. It's highly suggested to solder the

connection properly and use heat shrink tubing to seal it.

The table

below represents what the LEDs indicate on a non modified gauge

in wide resolution mode. You can use a Volt/Ohm meter on the

signal wire to take a reading directly from the O2 sensor to

recalibrate your lights in the fine resolution mode. These

should be pretty close, but don't hold me to these values.

LED 10 -

0.97V - 12.1:1 - Very Rich -

Forced induction and nitrous.

(All LEDs on)

LED 9 -

0.88V - 12.7:1

LED 8 -

0.78V - 13.2:1

LED 7 -

0.69V - 13.8:1

LED 6 -

0.59V - 14.4:1

LED 5 -

0.49V - 14.9:1 - Stoich- This is where NA motors should be at

LED 4 -

0.39V - 15.4:1

LED 3 -

0.30V - 16.0:1

LED 2 -

0.20V - 16.5:1

LED 1 - 0.10V -

17.1:1 - Lean (The only LED on)

Author:

85frankenstein |