|

Many

of our readers may be switching from a 4 cylinder to the DOHC,

which would either necessitate purchasing a front V-6 mount from

the salvage yard or manufacturing a new one from scratch. Dave

Ellis AKA ltlfrari has been so kind as to provide the specs as

well as a detailed write-up and pictures on how to manufacture

the mount. The following is his write-up in full.

This is my solution

to mounting my 95 3.4 DOHC onto an 85 cradle with a 5 speed

Isuzu transmission.

I replaced the standard tranny and engine mounts with West Coast

Fiero poly mounts. The tranny mounts are simple bolt up

replacements for the existing mounts so I will not go into

detail of those here.

As I was replacing a 4 cylinder engine with the 3.4 I did not

have an existing engine mounting plate that I could use. I had

read on Pennock's that an 88 V6 mount would work but when I

looked at how the end of the engine aligns above the (WCF)

engine mount I could not see how the bracket would fit in my

situation. This is not to say there is anything wrong with the

WCF mount just that so far as I can see a standard engine

mounting plate would not work.

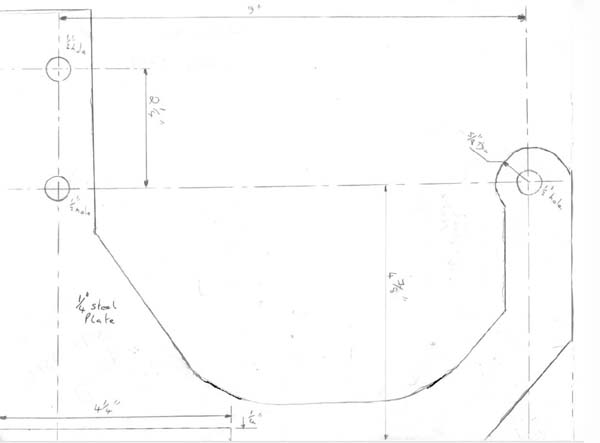

Figure 1 shows the basic engine mounting bracket that I had made

from 1/4 inch steel. I made some slight changes to the actual

bracket from the drawing. In particular I decided that the

cutout at the lower left of the bracket where the 'foot' goes

made that corner of the bracket too narrow so the cutout is not

only 2 1/4 inches long and I had the guy who made my bracket

notch the foot to match so that they interlock together.

The foot is simply a piece of 1/4 plate steel 4 1/4" x 2 1/2".

Click picture for a larger version

Figure 2 shows the completed mount. To drill the holes in the

foot I bolted the mount to the engine and installed the WCF

mount and marked where I wanted the bolt holes to go,

disassembled it and drilled the holes. I used the 3/8" bolts

that came with the WCF mounts.

Figure 3 shows the modifed WCF engine mount. Because the WCF

mount already had holes drilled in it that did not align with

the new holes in my bracket I had the existing holes welded up

and ground flat. Then I bolted it all up again, marked where the

holes in the foot matched the WCF bracket, removed everything

and drilled new holes in the WCF part.

Figure 4 and Figure 5 show the completed engine bracket in

place.

Author: Dave Ellis AKA ltlfrari

|